There are many different types of

commercial generators, and choosing the right one depends on specific needs (such as power, fuel availability, runtime, budget, and environmental requirements). The following is a detailed classification of the main commercial generator types:

I. Classification by Fuel/Energy Type (Core Classification)

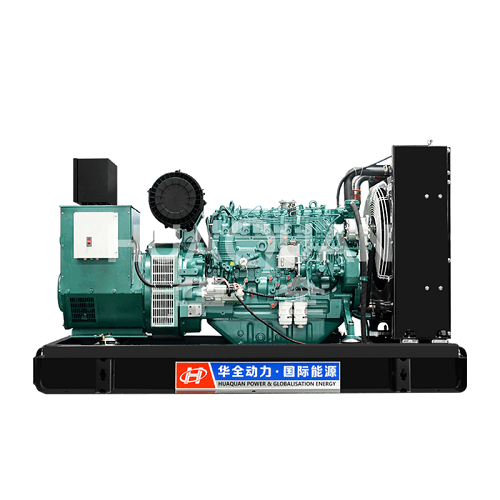

1. Diesel Generator:

The most common and widely used commercial generator type.

Advantages: High reliability, excellent durability, a wide power range (from a few kilowatts to several megawatts), relatively safe fuel (not prone to explosion), high thermal efficiency, relatively mature maintenance, and high initial torque (suitable for shock loads).

Disadvantages: High noise and vibration, relatively high emissions (particulate matter, nitrogen oxides), fluctuating fuel costs (typically more expensive than natural gas), and the need for regular maintenance.

Commercial Applications: Backup power (data centers, hospitals, factories, communication base stations), primary power (remote mining areas, construction sites), and mobile power supply vehicles.

2. Natural Gas Generator:

Very popular in areas with a stable natural gas pipeline supply, especially where environmental protection requirements are high. Advantages: Fuel costs are generally lower (especially pipeline gas), operation is clean (low emissions, minimal particulate matter), noise levels are lower than diesel engines, fuel supply is stable (pipeline), and maintenance intervals may be longer (cleaner combustion).

Disadvantages: Dependence on natural gas pipeline infrastructure (limiting deployment locations), gas pipeline outages result in system downtime (not as storable as diesel), initial purchase cost may be slightly higher, power density is generally slightly lower than a diesel engine of the same size, and efficiency may be slightly lower than diesel under extremely high loads.

3. Derivative Types:

Liquefied Petroleum Gas (LPG) Generators: Use propane or butane. Suitable for locations without natural gas pipelines but requiring clean combustion (such as rural commercial facilities and food processing plants). Fuel can be stored in tanks. Energy density is lower than natural gas, but costs may be higher.

Commercial Uses: Backup power (office buildings, shopping malls, hotels), primary power (operating in conjunction with the grid or in isolated grids), and as a foundation for combined heat and power generation.

4. Dual-Fuel/Multi-Fuel Generators:

Can switch between diesel and natural gas (or LPG), typically using natural gas as the primary fuel, with diesel as a pilot or backup fuel. Advantages: Flexibility, potential for fuel cost optimization (preferring cheaper natural gas), and improved operational reliability (using another fuel in the event of a fuel shortage).

Disadvantages: More complex system, potentially higher initial and maintenance costs.

Commercial Applications: Critical facilities requiring fuel supply flexibility (such as large hospitals and data centers), and preferred in areas with unstable natural gas supply.

5. Gasoline Generator:

Mainly suitable for small commercial or temporary commercial applications.

Advantages: Low initial cost, good portability (low power), and easy startup.

Disadvantages: Limited power range (rarely exceeding 20kW), highest fuel cost, less secure storage (volatile and flammable), short operating time (small fuel tank), frequent maintenance cycles, generally inferior durability and lifespan to diesel/natural gas generators, and higher emissions.

Commercial Applications: Temporary backup for small shops, mobile food trucks, powering small tools and lighting, and very small construction sites.

6. Biodiesel Generator:

Uses biodiesel made from vegetable oil or animal fat (typically in a blend such as B5 or B20). These are typically retrofitted to or compatible with existing diesel generators. Advantages: Renewable, reduces carbon emissions (from a lifecycle perspective), and has good lubricity (protects the engine).

Disadvantages: Cost is generally higher than petroleum diesel, low-temperature fluidity may be poor, long-term use may require cleaning of the fuel tank lines (it has a cleaning effect), storage stability requires attention, slightly lower energy density (slightly increased fuel consumption), and raw material sustainability is controversial.

Commercial Applications: Enterprises with clear environmental goals or policy requirements (such as green factories and industrial parks) and waste oil recycling projects.

7. Other (Emerging or Specific Applications):

Hydrogen Generators: Generate electricity by burning hydrogen or using fuel cells. Zero carbon emissions (only water vapor is produced during combustion). They are a key direction for future decarbonization, but current technology costs are high, hydrogen storage and transportation infrastructure is incomplete, and large-scale commercial use is still in its infancy.

Fuel Cells: Based on a different principle from the traditional internal combustion engine, they generate electricity through an electrochemical reaction (usually hydrogen or natural gas reforming). They offer high efficiency, ultra-low noise, and extremely low emissions. However, their current cost is extremely high, and their lifespan and durability need to be improved. They are primarily used in specific high-end backup power sources or microgrids.

II. Classification by Engine Type

1. Reciprocating Piston Engine:

The most mainstream type, including diesel, natural gas, and gasoline engines. Its structure is mature and reliable, and its application range is the widest.

2. Gas Turbine:

Commonly used in ultra-high-power power generation applications (several megawatts to hundreds of megawatts).

Advantages: Extremely high power density (high power in a small package), fast startup, low vibration, and relatively clean emissions (especially with great potential for NOx control).

Disadvantages: Very low partial-load efficiency (designed for near-full-load operation), very high initial investment, complex and costly maintenance, and high fuel quality requirements (clean gas or liquid fuel required).

Commercial Applications: Main units in large industrial combined-cycle power plants, ultra-large backup power sources for critical facilities (such as large airports and national data centers), and offshore platforms.

III. Classification by Operation Mode and Application

1. Standby/Emergency Generator:

The most prevalent commercial application. It automatically starts (typically within 10-30 seconds) upon a utility power failure to power critical loads. Power selection is primarily based on the needs of the most critical loads. Operating time is typically limited (a few hours to dozens of hours).

2. Prime/Standard Generator:

Operates continuously as the primary or sole source of power (either in an islanded operation or in parallel with a weak grid). Designed for 24/7 operation, they place extremely high demands on reliability, durability, and fuel efficiency. The power rating should meet the needs of all power loads.

3. Continuous Power:

Similar to prime generators, but with higher standards (e.g., data centers require zero downtime). Sometimes, they are combined with a UPS to provide seamless failover.

Peaking Generator:

Starts during peak hours to relieve grid pressure or capitalize on peak electricity price differences. Requires fast start-up and load-up capabilities.

4. Cogeneration:

While generating electricity, the generator can recover heat from engine exhaust and jacket water, using this heat for heating, cooling, or industrial processes. This significantly improves overall energy efficiency (reaching over 80%), making it a highly energy-efficient commercial solution. Fuel is typically natural gas or biomass.

IV. Other Key Classification Dimensions

1. Output Power Level:

Small Commercial: < 100 kW

Medium Commercial: 100 kW - 1 MW

Large Commercial: > 1 MW

2. Output Voltage and Phases:

Single-Phase (typically 120/240V): Small commercial applications

Three-Phase (208V, 240V, 480V, medium voltage such as 4160V): The workhorse for most commercial and industrial applications.

3. Installation Type:

Fixed: Permanently installed in a machine room or dedicated area.

Mobile:

Trailer: Mounted on a trailer for easy transportation to various construction sites or emergency response areas.

Vehicle-Mounted: Integrated into a truck chassis, becoming a power supply vehicle.

Portable: Small (mostly gasoline-powered) with wheels and handles.

Silent/Box-Type: The generator comes with a built-in soundproof enclosure, significantly reducing noise. Suitable for noise-sensitive environments such as urban areas, hospitals, and hotels. Containerized: The generator and its auxiliary systems are housed in a standard container for easy transportation, lifting, and protection, making it suitable for large projects or harsh outdoor environments.

Summary and Selection Recommendations

When selecting a commercial generator, consider the following key factors:

Primary purpose: Backup? Main? Continuous? Peak shaving? Combined heat and power generation?

Power requirements: Peak load, continuous load, and future expansion needs.

Fuel availability and cost: Is there an existing natural gas pipeline? Is diesel/LPG supply convenient and reliable? Long-term operating costs.

Operating environment requirements: Noise limits? Emission regulations? Installation space? Climate conditions (temperature, altitude)?

Budget: Initial investment vs. operating and maintenance costs.

Reliability requirements: Tolerance for power outages (for example, hospitals and data centers require extremely high reliability).

Maintenance capabilities: Is a professional maintenance team available or outsourced?

The most common commercial generator configuration is a fixed, three-phase output, diesel or natural gas-fueled, reciprocating engine-powered backup or main generator. The specific type to choose must be evaluated in detail based on actual needs and conditions and consult a professional supplier.

For more information, visit:

http://www.jizunet.com/