Diesel generators remain a reliable workhorse for backup power and off-grid energy solutions. To ensure optimal performance and longevity, it is critical to understand their core components and maintenance requirements. Here is a concise guide for operators and facility managers.

1. Core Components of a Diesel Generator

1. Engine

The heart of the system, typically a four-stroke diesel engine that converts fuel into mechanical energy.

Key components: cylinder block, piston, crankshaft and injectors.

2. Generator (alternator)

Uses electromagnetic induction to convert mechanical energy into electrical energy.

Key components: stator, rotor and voltage regulator.

3. Cooling System

Prevents overheating with liquid cooling (radiator) or air cooling.

Includes pumps, hoses and thermostats for temperature control.

4. Fuel System

Diesel is typically delivered from the tank to the engine using filters and a high-pressure pump.

Dual fuel filters (primary + secondary) are standard for protection against debris.

5. Lubrication System

Ensures smooth engine operation through oil pump, filter, and oil passages.

Regular oil analysis is essential to detect contaminants.

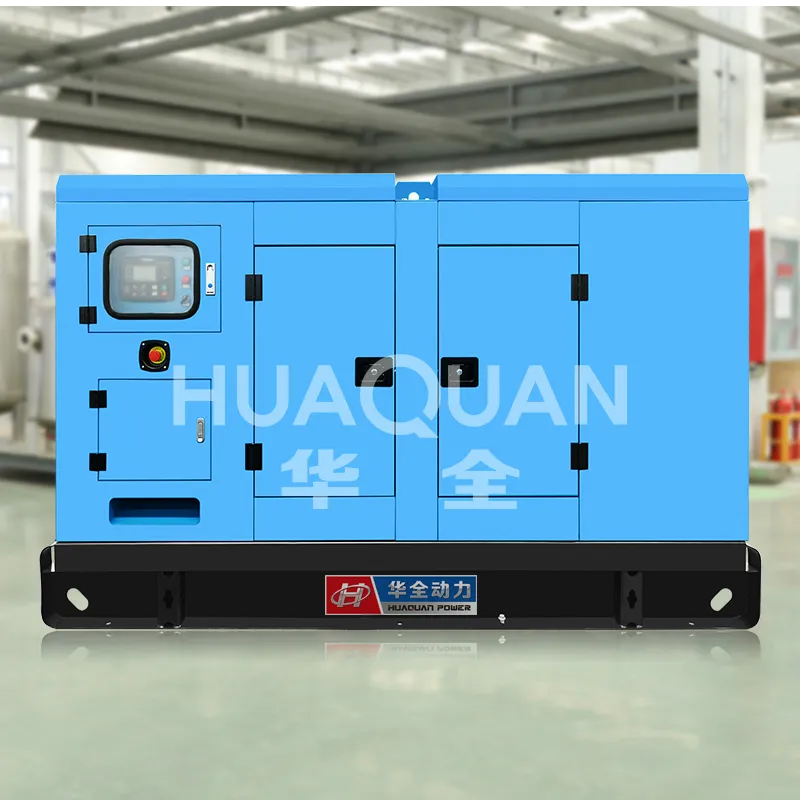

6. Control Panel

Manages start/stop functions, monitors voltage, and protects against overloads.

Modern panels often include digital displays and remote access.

Maintenance Practices for Peak Efficiency

2. Daily Inspection of Diesel Generators

Fuel Level: Keep tanks more than 1/4 full to avoid ingesting sediment.

Oil and Coolant: Confirm levels before starting; check for leaks.

Battery Voltage: Ensure starting power (12-24V DC systems).

Weekly/Monthly Tasks

Load Test: Run generator at 30-50% load for 30 minutes.

Filter Change: Change air, fuel, and oil filters every 200-300 hours.

Exhaust Inspection: Remove debris to prevent carbon monoxide risks.

Quarterly/Annual Deep Dive

Oil Change: Use OEM-specified oil (full synthetic oil recommended).

Spark Plug/Glow Plug Inspection: Clean or replace annually.

Fuel Polishing: Remove water and contaminants from diesel storage.

3. Seasonal Storage Tips for Diesel Generators

Add Fuel Stabilizer: Prevent performance degradation during extended downtime.

Mist Cylinder: Spray oil into the air intake to prevent rust.

Disconnect Battery: Store in a cool, dry place.

Final Thoughts

A well-maintained diesel generator can provide 15-20 years of service. Prioritize OEM parts, train operators to perform basic inspections, and work with local service providers to respond to emergencies. For mission-critical applications, consider dual generator redundancy.

For more information, please visit: http://www.jizunet.com/