In today's society,

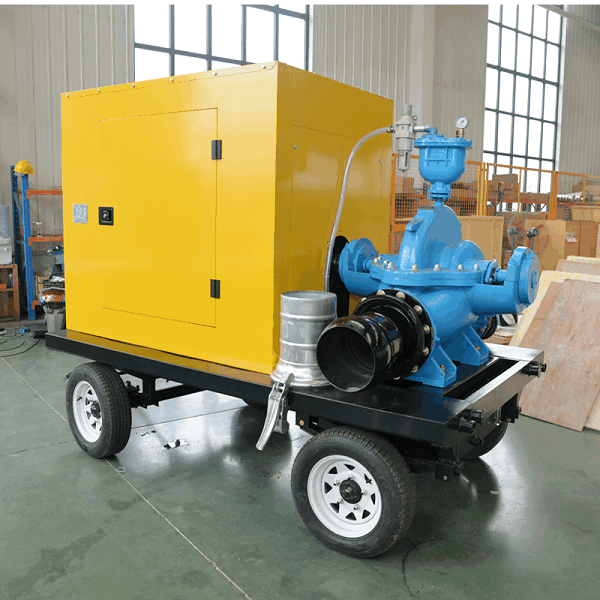

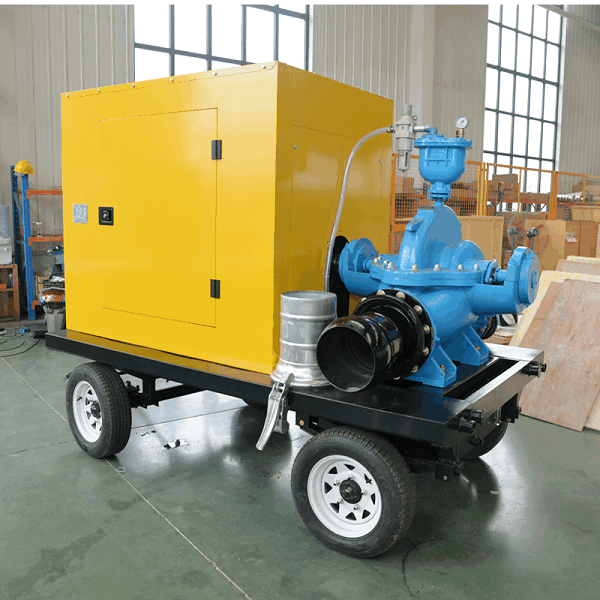

mobile diesel engine water pumps have become indispensable tools in agricultural irrigation, construction sites, emergency flood relief, and other fields, thanks to their high efficiency, convenience, and adaptability. Whether it's extreme climatic conditions or complex terrain environments, mobile diesel engine water pumps can provide stable and reliable water source solutions, saving users time and costs. In this article, we will explore in detail the working principle, main characteristics, application fields, and selection considerations of mobile diesel engine water pumps, to help consumers better understand and purchase this equipment.

Operating principle of mobile diesel engine water pump

A mobile diesel engine-driven water pump utilizes a diesel engine as its power source, driving the water pump to pump or transport liquids. The diesel engine generates kinetic energy through the combustion of diesel fuel, which in turn rotates the impeller inside the water pump, creating a certain pressure that allows the liquid to be drawn in and expelled. The internal structure of the water pump enables the fluid to gain momentum as it passes through, thus achieving efficient pumping. The entire process typically includes several stages: water suction, pressure increase, and water discharge, ensuring that the water pump can be flexibly applied in different situations.

Specifically, firstly, water enters the pump body through the inlet and is rotated by the impeller to form a flow. At the center of the impeller, the pressure of the water gradually increases, and through the rotation of the impeller, the water is quickly discharged to the outlet. The flow and pressure changes in this process enable good circulation of water suction and discharge, achieving high-efficiency pumping effect.

Main characteristics of mobile diesel engine water pumps

1. High efficiency: Compared to traditional electric water pumps, diesel engine water pumps often exhibit higher water output and head, making them particularly suitable for high-flow, high-pressure pumping applications and capable of meeting large-scale demands.

2. High adaptability: Mobile diesel engine-driven water pumps are not dependent on power sources and can operate in areas with power shortages or in wild environments, making them widely used for pumping tasks under various complex conditions.

3. Easy to move: Equipped with wheels and a handle, this design allows users to easily move between different locations, thus flexibly adapting to various operational needs.

4. Durability: The materials used in diesel engines are generally sturdy, and coupled with good maintenance, they can extend their service life and significantly reduce the occurrence of malfunctions.

5. Fuel economy: Compared to gasoline engines or electric motors, diesel engines offer higher fuel efficiency, exhibiting lower fuel consumption during prolonged operation.

Application Fields of Mobile Diesel Engine Water Pumps

1. Agricultural irrigation: Mobile diesel engine-driven water pumps are commonly used for irrigation of field crops and orchards, capable of quickly and efficiently pumping water into the fields and ensuring the necessary water for crop growth.

2. Construction site: During the construction process, a large amount of water is often required for concrete mixing, cleaning construction equipment, etc. Diesel engine-driven water pumps can efficiently provide the necessary water source.

3. Emergency disaster relief: In the event of natural disasters such as floods and typhoons, rapid drainage becomes a crucial task in emergency rescue and disaster relief. The high efficiency and portability of mobile diesel-powered water pumps make them essential equipment for rescue teams.

4. Municipal engineering: It is used in municipal drainage, river regulation, and other projects, ensuring the smooth flow of urban water systems, reducing the risk of flooding, and improving the quality of life for citizens.

5. Industrial Applications: In industries such as mining, petroleum, and chemical engineering, diesel engine-driven water pumps are commonly utilized for cleaning, cooling, or transporting liquid raw materials, playing a crucial role in ensuring industrial production.

Considerations for Choosing a Mobile Diesel Engine Water Pump

When purchasing a mobile diesel engine water pump, the following important factors need to be considered:

1. Performance parameters: Choose a suitable pump based on actual needs to meet the requirements of flow rate and head. Generally, the greater the flow rate and head, the higher the price of the equipment will be.

2. Brand and Service: Choosing water pump equipment from a well-known brand not only ensures better quality, but also provides more comprehensive after-sales service and technical support.

3. Fuel efficiency: Different models of diesel engine water pumps exhibit significant variations in fuel efficiency. Choosing a device with good fuel economy can significantly reduce expenses in subsequent use.

4. Maintainability: When purchasing, pay attention to whether the maintenance and upkeep of the water pump are convenient, and whether the replacement of parts is easy, to facilitate daily management and maintenance.

5. User Reviews: You can refer to the feedback from other users through channels such as the internet and forums to understand the actual performance and reliability of this model of water pump.

Conclusion

Mobile diesel engine water pumps are one of the indispensable practical devices in modern society. Due to their high efficiency and convenience, they are widely used in agriculture, construction, disaster relief, and other fields. Understanding its working principle and characteristics can help consumers make more informed decisions when faced with various water pump options. It is hoped that this article can provide you with some valuable information to help you become more proficient in your future work.

For more information, please visit:

http://www.jizunet.com/